Boiler & HRSG

Boiler & HRSG Inspection

HFS provides inspection resources, technology, and software to offer the most thorough and comprehensive boiler inspections, unlike any other boiler inspection company. HFS will provide the plant O&M team with the ability to PRIORITIZE and MONITOR corrective action, tracking the status of all repair recommendations. HFS will provide detailed reports with analysis and predictive failure information to determine an accurate current and future state of their boiler systems, along with repair recommendations to help minimize unscheduled (forced) outages.

HFS ensures its clients that a thorough and proper inspection is done during every outage, whether scheduled or unscheduled. Finally, HFS ensures repairs are conducted correctly, with no “shortcut” that would jeopardize the boiler’s integrity.

Our Services Include:

- General Inspection Service

- Inspection Planning and Supervision

- Detailed Visual Inspection

Boiler & HRSG Failure Analysis and Engineering Study

With more than 20 years of combined experience in managing a wide array of power plant projects, the team in our power generation division is known for delivering impeccable analysis and engineering studies for thermal power plants, co-generation power plants, and combined-cycle power plants. Aimed at assisting our clients in the upkeep and O&M (Operation and Maintenance) improvement of their existing fleets, HFS has developed the capability to service HRSG, IB, FH, and coal boilers and provide technical solutions to a wide range of reliability, performance, and emission issues. Our experienced and professional engineers can supply technical solutions when clients encounter issues or problems. HFS has been able to produce successful results for our clients, meeting their needs on time and within budget while supplying quality products. HFS works in the same time zone as the client.

Boiler Repair, Retrofit and Maintenance

HFS provides a comprehensive selection of boiler repair services.

Our Services Include:

- Retubing – Partial or complete retubing for water tube and firetube boilers.

- Welding & fabrication – All welding repairs; boiler shell plate, tube sheets, headers, stay bolts, handholes / manholes, faceplates, doors, breechings & supports. Pipe fabrication of steam, water & gas piping to ASME and/or API code, X-Ray quality welding.

- Appurtenances, Auxiliaries & Fittings – Safety, blowdown, stop & check valves; gauges, test connections, water column piping, feed pumps, cutoffs, preheaters and backflow preventers.

- Refractory – Firebrick chambers, burner tile, venturi rings, dry oven rings and all refractory repairs.

- Thermal & Acoustic Insulation – Mineral wool blanket & pipe covers, calcium magnesium silicate (CMS) repairs for interior & exterior of boiler.

- Mixing Valves – Rebuilding or replacement.

The retrofit and upgrading method to be adopted should be decided based on result of inspection and design review. HFS can evaluate current boiler or HRSG unit and recommend the right retrofit and upgrade package. HFS can provide Turn-Key EPC capacity and our service is include:

- PP (Pressure Part) replacement

Furnace wall replacement, Harp/semi harps/ module replacement, Bundle (coil) replacement, Link and Manifold pipe replacement - High energy piping replacement

- Air and Gas system replacement

Forced draft fan/ Primary air fan/ Air heater, Duct and casing upgrade. - Fuel feeding system replacement

Coal bunker, Coal feeder, Pulverizer, Fuel oil skid, Gas or Oil burner repair and addition. - SCR (Selective Catalytic Reduction) and CO system addition and replacement

- Partial tube leakage repair and/or replacement

- Expansion bellows and expansion joint retrofit and upgrade

- MOV/ CV/ Bypass Valves Re-engineering service

- Integral De-superheater (Attemperator) spray valve upgrade

- FCD (Flow Corrective Device) upgrade

- Leak detecting system, Life monitoring system application.

- Soot Blower

- Reverse Engineering

Boiler & HRSG Condition Assessment

HFS provide a genuine one stop option for all your inspection and assessment needs. We also offer condition assessment service with advanced NDE technology.

Our Services Include:

- Condition assessment services include:

- Remain life assessment and plant life extension

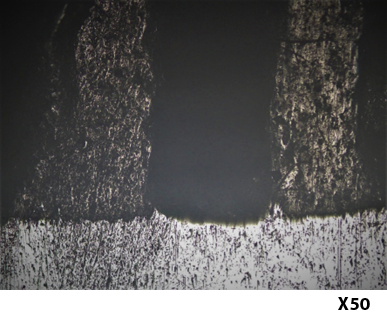

- Metallurgical condition review for high temp. components Thermal degradation, Fatigue, Creep

- Special NDE (PAUT)

- Portable hardness testing

- Metallographic replication

- Failure investigations and material assessment

- Remote visual inspection with borescope

- Pipe support surveys for both hot and cold condition

- High energy piping assessment

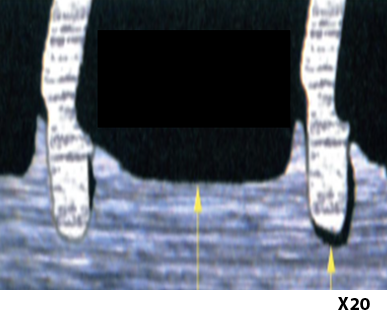

- FAC review

- Water chemistry review

- Walk down to identify start-up problems

- Specialized HRSG Condition Assessment

- Header Inspection – Specialized visual inspection technique to inspect headers for signs of Flow Accelerated Corrosion (FAC)

- Phased Array Butt Weld Scanner – Specialized device that uses phased array ultrasonics, combined with an encoded circumferential scan, to check the quality of butt welds on manual TIG / orbital pipe welds with diameters from 1.5″ to 4.5″.

- Water Chemistry Review / Corrosion Assessment – Corrosion risk assessment based on design, historical chemistry readings, applied chemistry concept and operation profile.

- Root Cause Analysis – For specific problems

S&S VALVE CO., LTD.

S&S VALVE CO., LTD. SAMSHIN LIMITED CO., LTD.

SAMSHIN LIMITED CO., LTD.

UNICON SYSTEM CO., LTD.

UNICON SYSTEM CO., LTD.