Valve Division

Being partnership with different top valve manufacturers worldwide, HFS is able to provide one stop solution to our customers not limited from supply to maintenance, we also provide reengineering services.

Valve Inspection, Repair and Reconditioning

Our Services Include:

1. Engineering Services

Good customer service & Engineering Services does not end with the sale, it is only the beginning.

We will support you with professional installation & commissioning, troubleshooting, and engineering service include reverse engineering of control valve.

2. Valve Maintenance & Services (All Type Of Valve)

- Service maintenance, overhaul & testing (workshop & In-situ)

- Valve preventive maintenance and corrective maintenance

- In-situ valves machining and services

- Valves flushing, lubrication & sealant on-site

- Manage and execute shut-down and preventive maintenance

- Actuator valve service and repair

- Fabricate and supply new parts (soft parts & metal parts)

- Supply competent manpower

3. Instrument / Electrical Maintenance, Service Testing & Re-calibration

- In-situ maintenance, service & overhaul

- Control valve on-site calibration

- Transmitter annual calibration

- Plant commissioning and start-up

- Control valve actuator refurbish and service

- Built-up control valve control panel and system

- Supply competent manpower

- Safety valves pop-test and recalibration on-site

4.Testing & Commissioning Services

This service includes installing, testing, commissioning and maintenance of various type of valves.

5. Supply Of Valve And Spare Parts

As an Authorized Distributor for S&S, Samshin, Unicon & SVC Valve in Malaysia and Singapore, we provide a wide range of valve products include control, cryogenic, manual, safety valve & the spare parts.

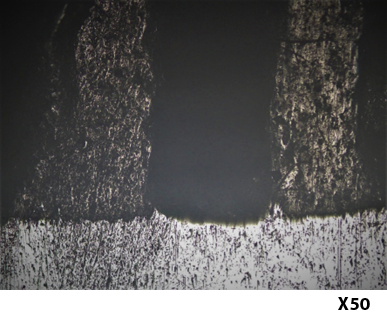

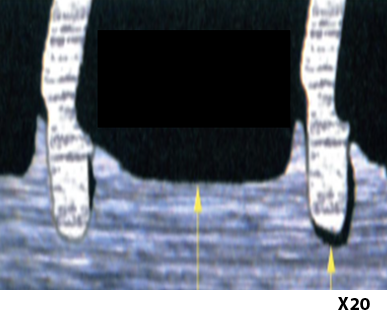

Reverse Engineering for Control Valve

Reverse Engineering Philosophy

In most cases, spare parts supplied by the customers are not compatible because they are obsolete, in other cases they are out of the production or the procurement times cannot be reconciled with the planning of maintenance and operations.

Reverse engineering is the process of extracting knowledge or design information by using 3D scanning data capturing system and redesign a used/new part of valve maker such as stem, trim, packing and so on. By undergoing reverse engineering, parts are not only be duplicated from the original but also improved and upgraded for better performance.

The construction and precision of the build components is guaranteed and attributed to the use of CNC multi-axis machining and turning centers, where the information extracted from the reverse engineering activity and the 3D modelling of the components to be built are perfectly integrated with production CAD/CAM system.

S&S VALVE CO., LTD.

S&S VALVE CO., LTD. SAMSHIN LIMITED CO., LTD.

SAMSHIN LIMITED CO., LTD.

UNICON SYSTEM CO., LTD.

UNICON SYSTEM CO., LTD.