Copyright © 2024-25 HFS HEAVY INDUSTRIES SDN BHD (200301011461 (613881-P)). ALL RIGHTS RESERVED.Website Designed by Xantec Johor Bahru.

UNICON SYSTEM CO., LTD.

UNICON SYSTEM CO., LTD.

| Specification of High Frequency Welded (HFW) Finned Tube | |

|---|---|

| Tube/Pipe Material | Carbon Steel, Stainless Steel, Copper, Inconel, Titanium |

| Fin Material | Carbon Steel, Stainless Steel, Copper, Aluminum |

| Tube/Pipe OD | 8.0mm ~ 219.1mm |

| Fin Type | Solid and Serrated |

| Fin Height | 5.0mm – 20mm( 50% of tube OD, up to 80% in special request) |

| Fin Thickness | 0.4mm ~ 3.0mm |

| Fin per Meter (FPM) | Max. 520 fin (based 0.4t fin) |

| Tube Length | Max. 27,000 mm |

| Application | – Oil & Gas: ACHE(Air cooled), HVAC, Economizer, Heat exchanger, Air Preheater, Fired Heater – Power plant: HRSG, Nuclear, GGH(Desulfurization) |

| Advantage of High Frequency Welded(HFW) Finned Tube vs Embedded Fin (G type) & Extrude Type | |

|---|---|

| Weldability | High Frequency Welded (HFW) can be applied dissimilar tube and fin welds instead of G-Type and Extrude Type |

| Efficiency | Higher heat exchange efficiency, 10% higher than G-Type, 15% higher than Extruded |

| Cost Save for Material | Tube material cost saving, 10% for G-type (0.3mm Groove), Much less for Extruded Type |

| Flexible Fin Pitch | Smaller and lighter equipment |

| Tube Size and Quantity | Minimum 10% reduce tube size and quantity |

| Higher Temperature | Applied to higher temperature depend on design temperature |

| Strong Durability & Maintenance | Strong durability with welded fin, Easy handling and waterjet washed. |

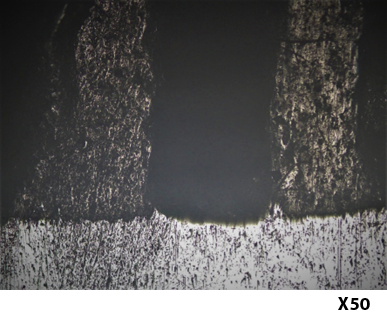

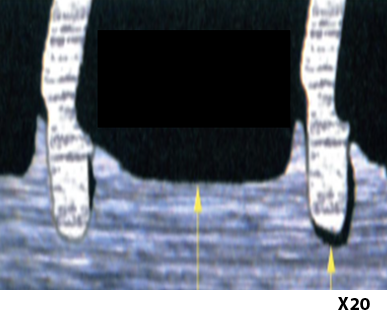

| Macro-Picture of Fin Connection Details | |

|---|---|

High Frequency Welded (HFW) Fin |

Embedded Fin (G type)

|