HFS Heavy Industries Sdn Bhd

Has come a long way to be recognized as a reputable industry player in Malaysia since establishment in 2003.

Discover More

HFS Heavy Industries Sdn Bhd

To become the industry leader renowned for spearheading the total suite of one-stop solution for engineering, fabrication, part supply, installation and services to raise infrastructure perfection to greater heights.

Discover More

Company History

Backed by more than a decade of experience in providing the total Engineering, Procurement and Construction (hereinafter in referred to as “EPC”) service for various industries, HFS Heavy Industries Sdn Bhd has come a long way to be recognized as a reputable industry player in Malaysia since establishment in 2003.

Through the year, HFS has honed our niche of providing state-of-the-art, total engineering and construction solutions via our total quality management approach to satisfy the needs of our clients from diverse industries.

Milestone

HFS Heavy Industries Sdn. Bhd.

2003

- Establishment

Doosan HRSG Service Distributor in Malaysia & Singapore

2015

- Accredited with ISO 9001:2008

Doosan HRSG Service Distributor in Malaysia & Singapore

2016

- Registered with CIDB Grade G7

HFS’s Power Generation Division

2017

- Accredited with ISO 45001

- Accredited with Boiler & UPV Repairer License From DOSH (BT21/661-PVR01/SBR01/SBR02)

Authorized dealers for 33 companies (Korea & Overseas) in Malaysia & Singapore

2021

Authorized dealers for 33 companies (Korea & Overseas) in Malaysia & Singapore

2023

- 1st HRSG & Power Conference in Malaysia Co-organised with MSIEA, Supported by DOSH

Authorized dealers for 33 companies (Korea & Overseas) in Malaysia & Singapore

2024

- “LEGATEST” in-situ safety valve testing (collaboration with VTM)

Products

Control Valve

MOV (Motor Operate Valve)

Desuperheater Valve

Top Entry Zero Leakage Valve

Bearing Refurbishment of Turbine

Actuator

Strainer

Steam Trap

Packing Gasket & Sealing

High Frequency Welded (HFW) Finned Tubes and Finning Machine Supply

Pipe Constant Hanger and Supports, Variable Hanger and Supports, Dynamic Elements

Expansion Bellows & Expansion Joint

Pressure Part & Piping Fabrication

Vent Silencer, Stack Silencer, Marine Silencer

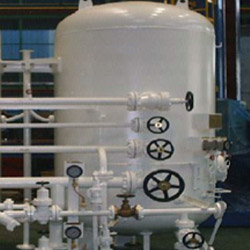

Deaerator, Blowdown Tank, Pressure Vessel

Crane

Bulk Handling Machine

Steel Plate, Steel Beam, Angle Bar, C-Channel, Flat Bar

Flange, Fitting, Blind, Spacer

Plate Rolling, Bending & Welded Tubular

Acoustic Horn

FLOWTECH’s Water Treatment System

Ballast Water Treatment System

Bottom Ashy Recycling Product

Military Equipment

Inspection

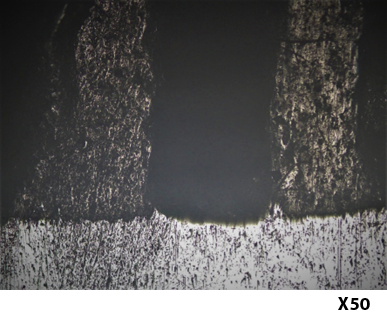

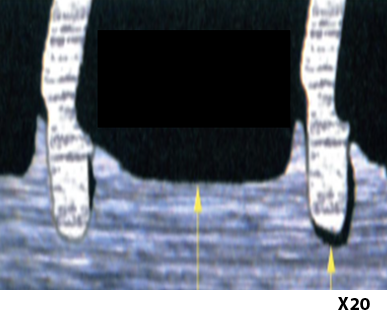

Boiler & HRSG Inspection

HFS provides inspection resources, technology and software to provide the most thorough and comprehensive boiler inspections unlike any other boiler inspection company.

Boiler & HRSG Failure Analysis and Engineering Study

The team in our power generation division is known for delivering impeccable analysis and engineering study for thermal power plants, co-generation power plants, combined-cycle power plants.

Boiler & Repair, Retrofit and Maintenance

HFS provides a comprehensive selection of boiler repair services.

Boiler & HRSG Condition Assessment

To provide a genuine one stop option for all your inspection and assessment needs, HFS also offer condition assessment service.

Piping Fabrication and Installation

Engineering Fabrication and Construction

Valve Inspection, Repair and Reconditioning

We will support you with professional services after sale.

Reverse Engineering for Control Valve

Maintenance to supply

Services

guided by our total quality management approach.

News and Event

Through the year, HFS

has honed our niche of providing state-of-the-art, total engineering and construction solutions via our total quality management approach to satisfy the needs of our clients from diverse industries.

S&S VALVE CO., LTD.

S&S VALVE CO., LTD. SAMSHIN LIMITED CO., LTD.

SAMSHIN LIMITED CO., LTD.

UNICON SYSTEM CO., LTD.

UNICON SYSTEM CO., LTD.